QUALITYEYE

for industry

EYYES offers intelligent quality inspection solutions specifically tailored to the needs of industry.

Safety and quality improvement in production

With the QUALITYEYE product suite based on the EYYES framework, we develop and deliver forward-looking applications for more safety in quality inspection for defect detection and surface inspection with artificial intelligence.

Applications

The camera-based sensor technology of the QUALITYEYE® product suite enables a wide range of applications using the framework.

Camera-based quality control

Inspection of a wide variety of surfaces

- Defect detection

- Defect classification

- Localised defect identification

- Comparative colour and gloss testing

Production process monitoring

Detection of deviations using deep learning algorithms

- Workpiece identification

- Position determination

- Geometry recognition

- Weld seam detection

Solutions for OEMs

Specific optical AI solutions for machine producers to expand their own portfolio of offerings, such as

- Tool monitoring

- Inline quality inspection

- Optical evaluation for process control

OUR SERVICES FOR YOU

Our services

- Consulting to determine the current status and the task/target

- Feasibility studies in our own lighting laboratory

- Project planning and implementation in hardware and software

- Implementation and trial operation

- Transfer of operations

- Support of the initial training and test phase

- Support and aftercare

.

.

.

SOLUTIONS

-

Surface inspection

Inspects the surface of a painted or coated workpiece to detect defects in the surface, e.g.

- Scratches, dents

- Enclosed bubbles

- Inclusions of foreign particles

- Insufficient deburring

- Deviations of color and gloss level

.

-

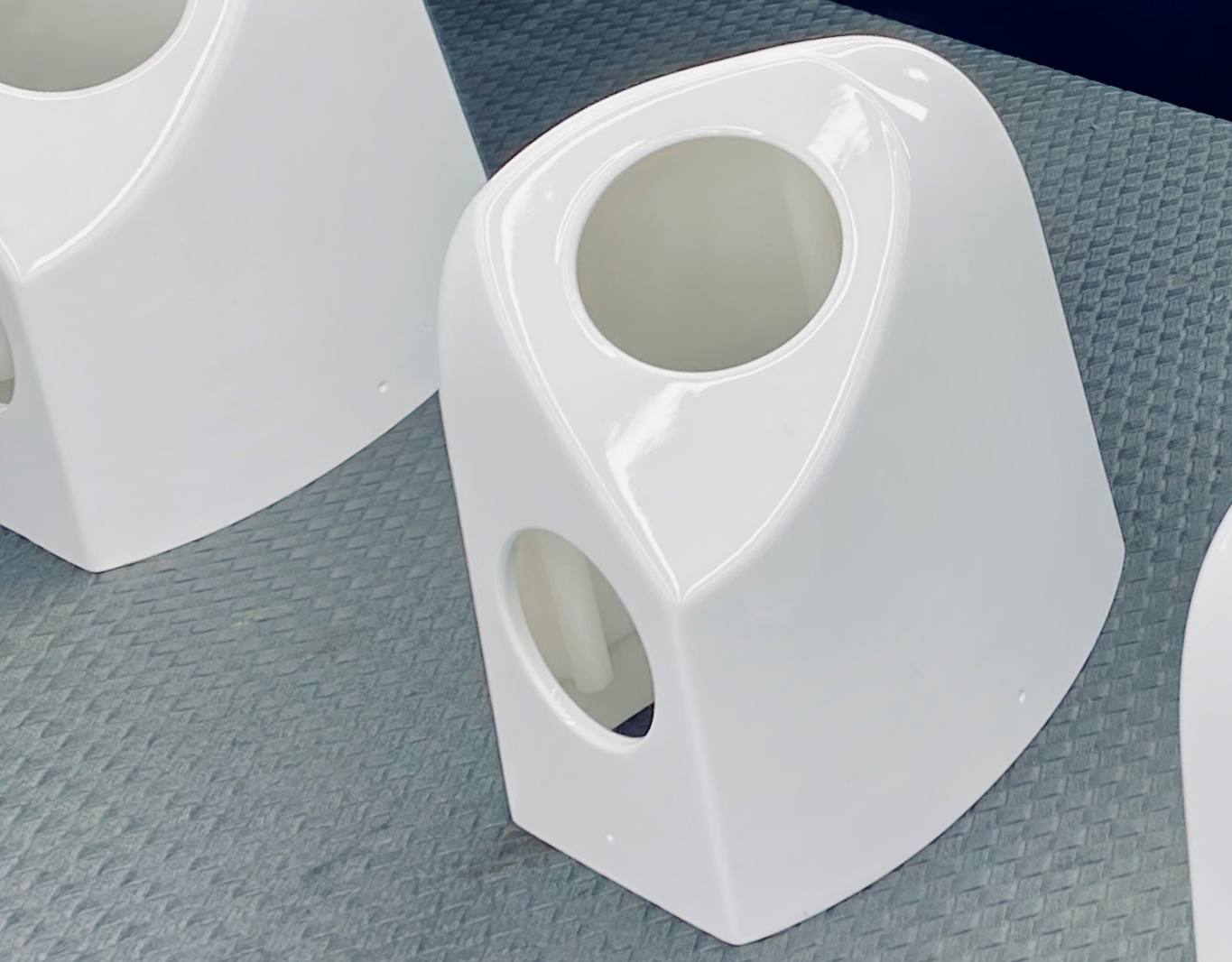

Injection molding

- Checks the dimensions of the product, e.g. for creep effects or spray defects

- Analyzes the color of the product, for example, by changes in the granules, color mist, paint runs, cloud formation

- Detects surface damage, e.g. scratches, dust inclusions, adhesive residues

- Even transparent components can be reliably inspected

.

.

.

.

-

Weld seam detection

- Real-time operation due to sampling rate of 90 fps

- 0% error rate

- >98% detection rate

- PLC interface to downstream industrial equipment

- Remote maintenance via VPN access

- Simple GUI for users

- Durable and robust

- Flexible design

.

.

INQUIRY